|

|||

|

|||

|

|||||

|

||||||||||||||||||||||||||||||||

| Parts Processing |

We excel at precision engineering based on assembling of the watch and movement part processing. Our parts department mainly deals with design and manufacturing of metal mold and press working. Our assembly department works with severe environmental conditions with a clean room of class 1000.

We can make a drawing of metal mold by CAD based on part or product drawings from our customers.

In addition, we can design assembly jig based on drawing specifications.

We produce consistently from design to manufacturing with our partner companies by facilities of Fig. 1-8.

Fig. 1: CAD |

Fig. 2: Machining |

Fig. 3: Wire Cut Electric Discharge Machine |

Fig. 4: Surface Grinding Machines |

Fig. 5: Profile Grinding Machine |

Fig. 6: Universal Grinding Machine |

Fig. 7: Three-dimensional Measuring Instrument |

Fig. 8: Machining Center |

We can provide scudding and unipotent punching for up to 350 x 550 mm mold size, and mold building for bending.

Fig. 9: 60 Ton Press |

Fig. 10: 30 Ton Press |

Lightweight processing (We excel at press working of minute products, its thickness is from 0.03 to 0.1 mm))

The following is a part of out products:

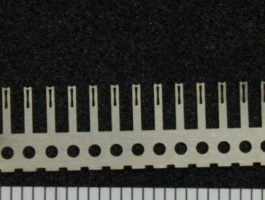

Fig. 11 |

Fig. 11 is a product using pure nickel materials, and the thickness of materials is from 0.1 to 0.3 mm. The slit width of the right product is 0.5 mm. In addition, in the case of the left product, burr height is managed in 0.02 mm or less. |

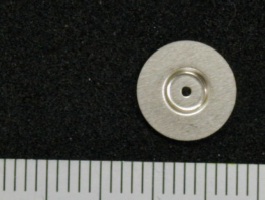

Fig. 12 |

Fig.12 is also pure nickel materials, but squeezes a center. |

Fig. 13 |

Fig.13 uses nickel silver materials, and the thickness of materials is 0.05 mm. The width of the ellipse part of the product tip is 0.2 mm. |

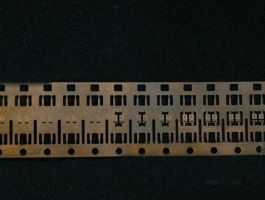

Fig. 14 |

Fig.14 uses brass. |

Fig. 15 |

Fig.15 uses beryllium copper. In addition, this product is bended. |

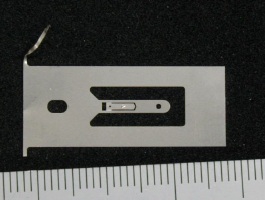

Fig. 16 |

Fig.16 uses SUS304. The thickness is 0.05 mm, and U-shaped slit width is 0.1mm. In addition, protrusion of the emboss and two step bending is applied. |

Fig. 17 |

Fig.17 uses SUS631. The thickness is 0.25 mm. The width of the thinnest part is 0.2 mm, narrower than thickness. |

Fig. 18 |

The material of Fig.18 is phosphor bronze. |

Fig. 19 |

Fig.19 is a part for watches, and the material is beryllium copper. |

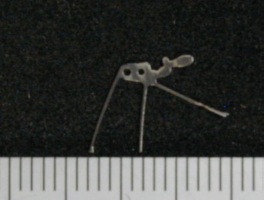

Fig. 20 |

Fig.20 is a part for quartz watches which uses SUS304 spring materials. |

|

|