|

|||

|

|||

|

|||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

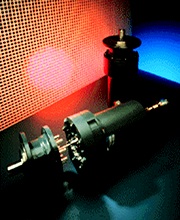

Empire Magnetics provides quality motor products designed to perform in environments and applications where ordinary motors are unsuitable. Custom systems and modifications are available upon request. |

| - | MOTORS Brushless Motors, Stepper Motors, AC Motors, DC Motors |

| - | RESOLVERS Motor Mounted & Stand Alone |

| - | RDE Resolver-to-digital converter |

| - | Gearheads, Brakes, Cables, Mechanical Modifications |

Product Information

|

The following nine products are available with a variety of size, torque and power consumption. |

| (1) |

Vacuum Grades Laboratory, Standard and Commercial Grades are available.

|

||||||

| (2) |

Radiation Hardened Products High energy gamma radiation will attack all of the materials in a device, however the non-metallic materials in a motor or resolver are subject to more rapid breakdown. Lubricants, varnish, adhesives, insulations, and cables deteriorate and ultimately crumble. Empire Magnetics radiation hardened (RH-) products combine the best available radiation resistant materials with practical commercial practices to provide products with the longest possible service life within pragmatic budgetary considerations. |

||||||

| (3) |

Submersible Waterproof Products Stainless steel housed steppers and A.C. induction motors provide corrosion resistance, and easy to clean features. The stainless steel packages are useful in nuclear reactor applications, while the A.C. motors are frequently found in the food processing industry. |

||||||

| (4) |

Dustproof Products Features include built-in O ring seals that eliminate dust leaks at potential penetration points, motor insulation that allows operating at 145°C, case temperature (185°C winding temperature) and air fittings for pressurization are supplied; pressure rated to 15 psi to lock out contamination. |

||||||

| (5) |

Abrasive Dustproof Products

Features include, built-in O ring seals that eliminate dust leaks at potential penetration points, housing seals including a shaft slinger and seal prevent abrasive dust from entering the bearing, motor insulation that allows operating at 145°C, case temperature (185°C winding temperature) and air fittings for pressurization are supplied; pressure rated to 15 psi to lock out contamination. |

||||||

| (6) |

Hazardous Area Motors

Two commonly used methods are Explosion Proof (EP) and Purged and Pressurized (PT). Explosion Proof devices are intended to withstand and contain an expected explosion, Purged and Pressurized systems are intended to prevent an explosion from occurring. |

||||||

| (7) |

Extended Temperature Products

In typical stepper motor applications these motors will operate successfully up to +155°C. Provided the change in temperature does not exceed 10°C. per minute, these motors can be used in a very wide range of temperatures. The HT series products without modifications are useful from 0 to about +155°C. For temperatures from 0 to -20°C most of the HT products can be used, but different lubrications are required. From -20 to -40°C some select products are suitable. |

||||||

| (8) |

Cryogenic Products Cryogenic temperatures (to 20 degrees Kelvin) call for motors designed with materials carefully selected for compatible thermal expansion characteristics and resistance to brittleness. CY Series motors feature special cryogenic dry lubrication and proprietary metal and or metal alloy components. |

||||||

| (9) |

Industrial Grade Products

Empire Magnetics offers the Industrial grade (IN- versions) which provide the same performance characteristics as the environmentally conditioned products, but we use commercially accepted materials and mechanical configurations to keep the cost low. If you are just starting a project, the IN- versions may provide the least cost and the shortest time to testing a prototype. |

||||||

Important Note about the Power Supply and Repair

Power supply of some products is adapted to Japanese 100V specifications. In case of using it outside of Japan, please be sure to use a voltage converter for each country/area.Also, when you need to repair the products purchased from Pulse Denshi, please send them back to us so we can offer repair cost estimates. Your local service center may not accept such repair.

Company and product names mentioned in this website are trademarks of their respective owners.

All information and specifications are subject to change without notice.

All rights reserved. No part of this website may be reproduced.

All information and specifications are subject to change without notice.

All rights reserved. No part of this website may be reproduced.

|

|